Best Timing for Roofing Membrane Repairs

Spring offers moderate temperatures ideal for membrane repairs, reducing the risk of material issues caused by extreme weather.

Summer provides longer daylight hours and warmer weather, facilitating timely repairs before colder seasons.

Fall is suitable for repairs to prevent winter damage, with cooler temperatures ensuring proper adhesion of roofing materials.

Ways to make Roofing Membrane Repairs work in tight or awkward layouts.

Popular materials for Roofing Membrane Repairs and why they hold up over time.

Simple add-ons that improve Roofing Membrane Repairs without blowing the budget.

High-end options that actually feel worth it for Roofing Membrane Repairs.

Finishes and colors that play nicely with Roofing Membrane Repairs.

Optimal timing for membrane repairs depends on climate, weather conditions, and roof usage. Conducting inspections during mild weather seasons allows for effective repairs with minimal disruption. Neglecting repairs can lead to significant damage, including mold growth, structural deterioration, and increased energy costs. Regular maintenance and early intervention are key to preserving roof performance and avoiding costly replacements.

Cracks, blisters, or punctures indicate the need for repairs to prevent leaks and further deterioration.

Extreme cold or heat can affect membrane adhesion and flexibility, making repairs less effective during harsh weather.

Regular inspections in spring and fall help identify issues early, ensuring timely repairs and extending membrane lifespan.

Choosing the right membrane material for the climate ensures durability and ease of repair during optimal seasons.

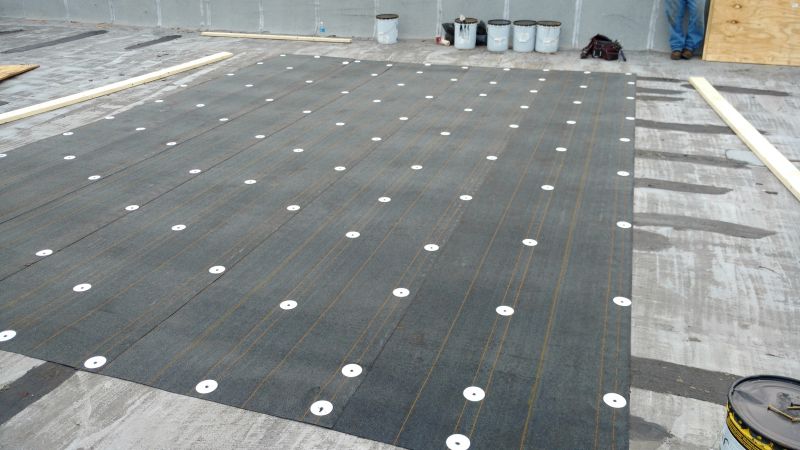

A detailed view of membrane patching and sealing techniques.

High-quality materials designed to withstand seasonal temperature fluctuations.

Technicians assessing membrane integrity during a routine check.

Cleaning and surface preparation prior to membrane patching.

Finished membrane patch with seamless sealing.

Specialized equipment used for welding and adhesive application.

| Season | Ideal Repair Conditions |

|---|---|

| Spring | Moderate temperatures, low humidity, optimal for adhesion. |

| Summer | Warm weather, longer daylight, ideal for repairs. |

| Fall | Cooler temperatures, dry conditions, good for preparation. |

| Winter | Cold and wet conditions, less suitable for repairs. |

| Late Spring | Stable weather, minimal rain, suitable for repairs. |

| Early Fall | Temperate weather, lower humidity, ideal for repairs. |

Timely roofing membrane repairs are crucial for maintaining roof performance and preventing costly damage. Conducting inspections and repairs during favorable weather conditions ensures effective adhesion, sealing, and longevity of membrane materials. Regular assessments, especially before winter and after severe weather events, help identify issues early. Proper timing combined with professional expertise can significantly extend the service life of roofing membranes.

Technicians applying patching materials during optimal weather.

Finished repair with seamless sealing for durability.

Tools used for detecting membrane damage and assessing conditions.

Final look of a properly repaired roofing membrane.

Little measurements that prevent headaches on Roofing Membrane Repairs day.

A 60-second routine that keeps Roofing Membrane Repairs looking new.

A frequent mistake in Roofing Membrane Repairs and how to dodge it.

Small tweaks to make Roofing Membrane Repairs safer and easier to use.

Interested in roofing membrane repairs? Filling out the contact form provides an opportunity to discuss options, schedule inspections, or request a detailed assessment tailored to specific roof conditions.